|

Rethink the Rack: Maximizing Warehouse Efficiency with Diverse Storage SolutionsOn the surface, warehouse racking is pretty straightforward: upright frames and horizontal beams work in tandem to support both palletized and non-palletized goods. But when you peel back the layers a bit it’s clear that racking is not “one-size-fits-all” for the typical DC or warehouse. Certain products require different types of racking; storage needs vary from one company to the next; and everything from seismic features to fire ratings must be factored into the equation. These and other variables are forcing companies to “rethink the rack” and explore alternatives to traditional selective racking. Download this whitepaper to explore that while traditional selective pallet racking is a versatile option, it’s not always the best fit for every facility. |

|

How to Choose the Right Pallet Racking for Your Cold Storage NeedsIn today’s world, there are several options when it comes to improving efficiencies in cold storage. Some are tried and true, and others, like automation, are quickly gaining traction. While it’s easy to start mentally gravitating toward a full-blown automated storage and retrieval system, finding the right solution or solutions for your warehouse today means evaluating the space you have and planning a solution that will work within it. Download this whitepaper to explore the options to help you choose the right pallet racking for your cold storage needs. |

|

When it Comes to Pallet Rack Systems, Cheaper is Definitely not BetterShopping on price can work in some scenarios, but sacrificing quality, features, safety and warranties in exchange for cheaper pallet rack systems is a bad idea in today’s warehousing and distribution environment. Price is of course an important factor to consider when shopping around, but you should also know that the cheapest product rarely delivers the lowest total cost of ownership (TCO). Download this whitepaper to understand how total cost of ownership and risk avoidance are critical when buying new pallet rack systems. |

|

10 Things to Consider When Outfitting your WarehouseWhen it comes time to outfit your warehouse with a racking system, it can be hard to know where to start. Not every warehouse or project is the same, and in order to determine your ideal storage solution, there are multiple safety and design factors to consider. Download this whitepaper to help you find the most efficient storage solution for your warehouse. |

|

Pallet Rack Safety GuideEven the best-built pallet rack can sustain damage. When racks are damaged, it can compromise a rack’s capacity and put your system at risk.

Download this guide to learn what you can do to protect your investment. |

|

10 Most Frequent OSHA Citations and How to Be Prepared

No one wants to experience an OSHA inspection. But when you consider the implications of even a single injured-worker incident, it is well worth the time investment to ensure any facility hazards are minimized and your staff is thoroughly trained. Download this whitepaper to learn how a design review will help you. |

|

|

Rack Planning Design Guide

A guide to selecting the right rack type Whether planning for a new system installation or a rack replacement, warehouse operators are often confronted with an overwhelming number of choices. Matching business needs with the appropriate rack system is critical and entails asking the right questions, as well as planning for the flexibility to adapt as your business grows and evolves. Download this guide to help you avoid common pitfalls in designing your new system and selecting the right rack type. |

|

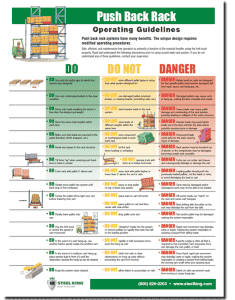

Push Back Rack Operating GuidelinesAn On-Site Guide for Safe, Efficient, and Maintenance-Free Operation Push back rack systems have many benefits, but their unique design requires modified operating procedures. Material handlers using the fork trucks with push back rack systems should read and understand the following instructions prior to using a push back rack system. Download this guide for safe, efficient, and maintenance-free operation. |

| Rack Systems Done Right Whitepaper

Wading through the details of planning a new rack system that is both cost-effective and efficient can be daunting. From permitting to workflow to seismic zones, this hands-on whitepaper will help you reap the maximum benefit from a design review, and will walk you through steps to help you avoid many of the pitfalls that can cost you both time and money. Download this whitepaper to learn how a design review will help you. |