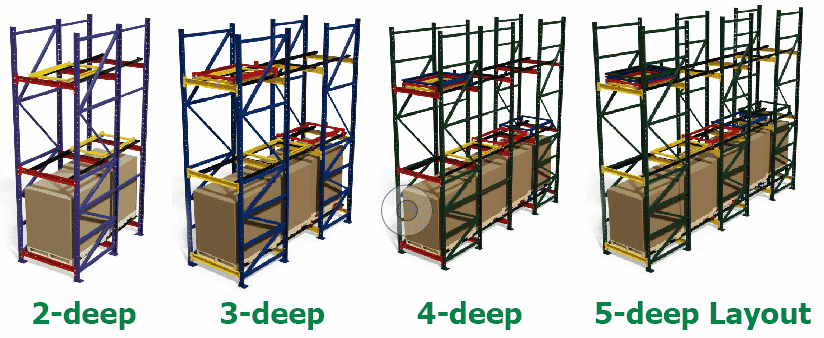

The SK3600® pushback racking system is ideal for Last In, First Out (LIFO) inventory management. This high-density storage solution allows you to store pallets 2- to 5-deep, maximizing space efficiency while retaining easy access to a wide range of SKUs. Each level or lane of the push-back rack system is independently accessible, allowing up to 90% more product storage than selective rack systems.

Unlike other high-density systems such as drive-in racking, push-back racking provides independent access to each level. This design optimizes selectivity and reduces the number of aisles and forklifts needed, leading to improved operational efficiency and cost savings.

Push-back racking utilizes nested carts that ride on inclined rails. Pallets are placed onto the carts by forklift and pushed back by subsequent pallets, creating a LIFO storage system. During unloading, the front pallet is removed, allowing the remaining carts to roll smoothly forward.

With Steel King manufacturing both the cart system and racking, you’re always assured a perfect fit for your push-back racking system. Carts are welded for maximum durability and require no field-assembly, ensuring they are always square and ready for use. Heavy-duty components provide capacities of up to 3,000 pounds per cart, and the supporting rack structure can be designed using either our SK2000® roll-form rack design or our SK3000® structural channel rack to meet specific capacity requirements.

Regardless of your product load and working environment, Steel King’s engineering team can design a system to fit your need. This rack-supported freezer facility was designed as a space-efficient expansion with insulated panels attached to the sides and top to form sidewalls and a roof.

Related Stories:

|

‘Sweet’ Addition Of Storage For A Growing Ingredients Manufacturer Denali Ingredients creates efficient new space to facilitate rapid growth of their operations |

|

Rack-supported addition helps Vieira’s Bakery optimize production Rack-supported addition helps Vieira’s Bakery optimize production |

|

Enhancing Storage to Accommodate New Product Launch Hyundai Powertech optimizes storage to make room for new product launch |

|

Top cart of any depth pushback comes with a center stop restricting the pallet from hanging over the rear of the cart. Acts as a holding stop not allowing pallets placed after the 1st pallet to push this 1st pallet off the cart. Note This applies to 3, 4 and 5 deep pushback systems. |

|

A stop plate on the rear of the pushback lane stops carts from being pushed off the rear of the system. |

|

Interlocking tabs between carts. When pushing the top cart back it comes in contact with the lower cart, moving the cart indicating that the next pallet can be placed on the cart. When unloading the lower cart comes in contact pulling the top cart forward. |

|

Hold down angle. Pallets at times can form onto the cart when placed for long periods of time. When unloading, the pallet may lift the cart up, this angle will not allow the cart to be lifted with the pallet. |

|

Full width angles welded to the bottom of the lane to maintain spacing between rails. The angles rest on top and vertically against the beams to eliminate twisting and offer a tight fit. |

|

| Pushback rails are bolted to the front beam, through prepunched holes which are designed specifically to the system. Two extra holes in the center of the rail on the beam are supplied for optional add on weak pallet rail support or pallet stop. If a pallet changes and requires one or the other, a quick bolt in solution is in place in lieu of field drilling or new components for existing parts. |

| Rack | Designed with 55,000 psi high strength steel and can be custom designed for your specific pallet. |

| Bed Rails | The bed rail is a one-piece welded construction with easy, drop-in installation. |

| Carts | Heavy, four-sided carts provide a large target area for loading and unloading. – Carts ship pre-assembled, ensuring components are square and operate smoothly Interlocking carts alleviate jamming and damage – Each cart is a different color for color-coded “inventory at a glance” Optional cart accessories include pallet supports for weak pallets or wire decks. |

| Wheels | Four (4) 8620 chrome-plated, hardened steel wheels per cart. – Dust- and debris-resistant bearings – 2,000 LB load capacity per wheel |

| Finish | Highly durable, powder coat paint finish offers better gloss, hardness, and adhesion than typical enamel paints – Greater resistance to fork truck impact, solvents, and corrosion – Environmentally friendly. |

| Options | Wire-deck carts  |