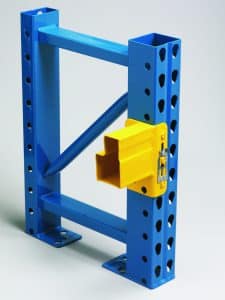

Closed-Tube Steel Components Provide Increased Racking Impact Resistance

Posted on Feb 17, 2023

The value of Steel King’s SK2000 and SK2500 over open-back racking

It’s inevitable that forklifts will bump into pallet-racking components in warehouses and distribution centers. That’s true no matter what type or brand of racking is selected. But when comparing components made from roll-formed steel, there is a marked difference in the ability of the racking to withstand such impacts.

Open back rack vs closed tubular racking

The Advantages of Steel King’s Closed-Tube Rack Design Over Open-Back Racking

Most manufacturers use roll-formed steel for columns, braces, and beams of some types of racking systems, because that steel is lightweight compared to structural steel, while still offering the strength a racking system needs. But Steel King adds to the durability of roll-formed steel by fully welding the back side, so all the components become closed tubes, says Kurt Larson, a Regional Sales Manager with Steel King.

“Other manufacturers use open-back components, or if they have a closed-tube option, not all the components are closed, or the welding is different from Steel King’s,” Larson adds.

“There are manufacturers who use closed-tube steel, but they use a different design – one that is close to ours but that does not call for the use of closed tubing for all components,” he points out.

Steel King uses a roll-form steel closed-tube rack design for all components of its SK2000 boltless tubular and SK2500 bolted closed-tube racking systems. Both systems are widely used in the material handling industry.

“On our SK2000 and SK2500 systems, everything is fully tubed – the posts/columns, the diagonal braces, and the horizontal braces. And the welding that creates the closed tubes for each of those components is top quality,” he adds. “These are very important features of our systems – features that will let the end user focus on material handling instead of racking maintenance,” he emphasizes.

Greater Impact Resistance For Increased Security

Independent tests have shown that racking made with closed-tube components has a far greater ability to withstand impacts from forklifts and other vehicles, compared to open-back framing. Additionally, impact resistance is especially valuable in fast-paced environments, such as cold storage facilities and high-volume distribution centers.

When compared to a comparable open-back column, the tests showed Steel King’s closed-tube racking to have:

- 250 percent more frontal impact strength

- 44 times more twist resistance

- 68 percent more side impact resistance

“This is factual data determined in independent studies,” Larson notes.

A Tubular Racking System Can Lower Your Cost of Ownership

Steel King Closed tube

With added durability provided through Steel King’s closed-tube rack design, less maintenance will be required. Also, risks to employees and to stored goods could be reduced, as structural failures could be less likely.

“Our design and manufacturing process creates racking that will require less maintenance, and thus the overall cost of ownership of the Steel King system will be less,” Larson notes.

The closed-tube feature not only offers greater impact resistance but is also preferred for use in food and beverage, pharmaceuticals, and agriculture markets because the closed-tube prevents the accumulation of debris that could happen with an open-back system.

Components of the SK2000 and SK2500 systems have a 90-degree bend and no corner holes – features that add to the structural integrity.

“Our tubes have a true 90-degree angle, while other manufacturers have rounded corners,” Larson notes, adding that “the more bends you have in steel, the stronger it becomes. The fact that our tubes do not have corner holes is a very important feature that adds to the integrity of the racking,” he adds.

Selecting The Right Steel King Racking System For Your Storage Needs

Steel King only uses American-made steel for its racking components. Its closed-tube beams are available in many profiles and lengths and, like all components of a racking system, can be powder-coated in a variety of standard or custom colors.

SK2000 racking is ideal for selective and double-deep selective systems, pick modules, and carton flow systems.

SK2500 is commonly used for push-back, pallet flow, drive-in, drive-through, and mini-load ASRS (automated storage and retrieval) systems.

“When you are looking at any of those types of pallet racking, Steel King’s approach of enclosing all roll-formed steel components will give you a top quality system that will better withstand heavy use,” Larson says.

View Our Full Selection of Racking Systems